There are a number of reasons why improving food safety and sanitation should be a priority for any food plant. It reduces the chances of food contamination and ensures high food quality which is essential. There are strict guidelines food plants need to adhere to and managers and operators are tasked with implementing these requirements to the letter.

Elements of Cleaning and Sanitizing

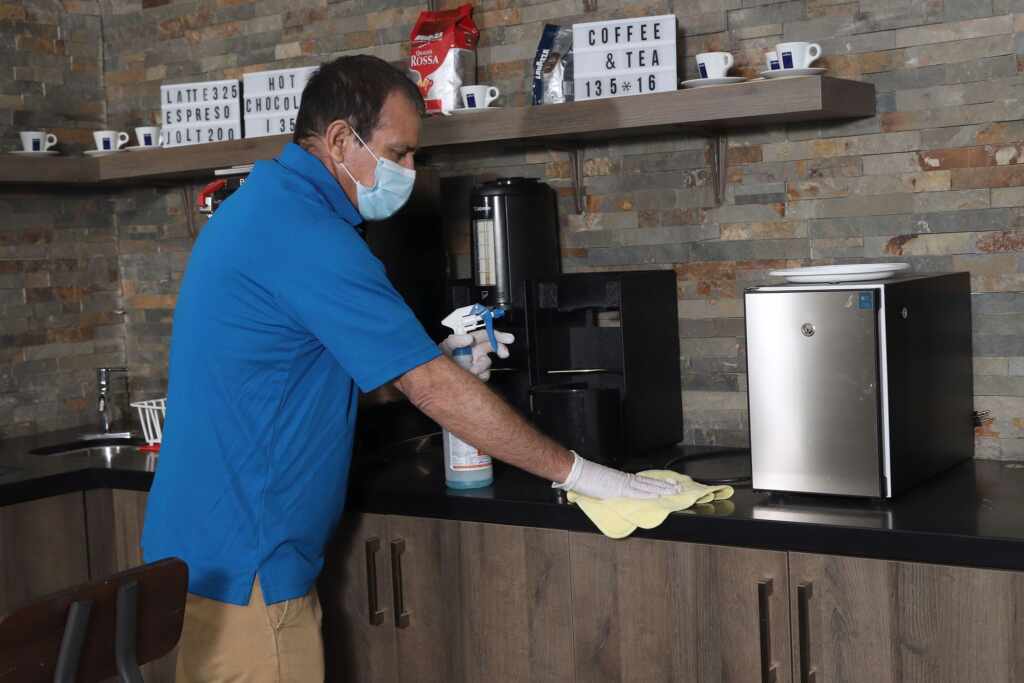

So, what is the difference between cleaning and sanitizing? Cleaning is wiping away or removing visible food particles or food stains from surfaces manually or using chemical processes. Sanitizing goes a step further by treating the area with a chemical that destroys harmful germs and bacteria. Proper food plant sanitation will prevent foodborne illnesses and maintain a clean working space.

Cleaning and sanitizing equipment can be done in several ways. You can use clean-in-place (CIP) methods, foaming, clean-out-of-place (COP), spraying, high pressure and manual methods. Regardless of the type of cleaning and sanitation method you choose, the common components of effective sanitation are summed up using the acronym TACT WINS.

T = time

A = action

C = concentration

T = temperature

W = water

I = individual

N = nature

S = surface

- Time – For a surface to be properly cleaned, the cleaning agent needs time to work. However, it must be given the right amount of time for the solution. Too much or too little time is both problematic.

- Action – some form of energy is needed to clean a surface. This allows the cleaning agents within the cleaning solution to interact with the dirt and help remove it.

- Concentration – this is extremely important because for the solution to work properly, there needs to be the correct amount of cleaning agent. Adding too much of the cleaning solution may cause damage to the surface of the equipment and too little will reduce the efficacy of the cleaner.

- Temperature – there is an optimal temperature range for every cleaner that you use. Generally, the efficacy of a cleaner is doubled for every 10°C increased in temperature.

- Water – this is necessary at several points. First to rinse off the equipment before applying your cleaning solution. Water is also often used to transport the detergent along the surface and wash away the dirt.

- Individual – the person who is doing the cleaning or sanitation needs to have the proper training and equipment to adequately complete the task.

- Nature – the types of soil that need to be removed from the equipment is determined by the type of plants brought to the facility. Different types of soils have unique properties and it’s important to be mindful of the type of food allergens that are introduced to the food plant based on the products being processed.

- Surface – the material that the equipment is made from plays a huge part in determining the best type of cleaning solution and method to use. For example, metals corrode, so the type of cleaning solution you use needs to be compatible with the material the surface is made of.

The Three C’s of Cleaning

Consider Sanitation Setup

The layout of your equipment should be designed to improve efficiency and minimize contamination. In addition to strategically placing your equipment in the food plant, consider a sanitation room where workers can go through prior to beginning their work. Germs from the bathroom may find their way to areas where food is processed if the bathrooms are ill-designed i.e. bathrooms doors that open towards the area where food is processed.

Clear Away Dirt, Dust and Debris

Dust and dirt can be very detrimental to the equipment used in a food plant and possibly contaminate food products. Therefore, it’s important to clean equipment regularly to remove dirt and debris as part of your food sanitation routine. Since dirt often has a way of finding its way indoors, workers should wear protective gear over their shoes to prevent dirt from being introduced to the food facility.

Choose the Right Drainage

Proper drainage is essential in food plants because it eliminates wastewater from the floors of the facility. Allowing standing water to accumulate in the facility spells trouble because it attracts bacteria and provides the perfect environment for it to breed, which can lead to huge contamination issues. A good drainage system will combat this.

Invest in Equipment

Your facility can only produce the best food products if it has high-quality equipment. When you invest in quality equipment, you can count on it to last longer and be more efficient than cheaper equipment. We suggest purchasing equipment that is stainless steel since this metal is resistant to bacteria and does not corrode. Another reason why the equipment should be high quality is because you don’t want to worry about parts of your equipment chipping off and ending up in your food.

Work with Pest Control

Pests in a food plant are a big no-no. Not only are they unsightly, they can introduce dirt and bacteria to your food and cause a lot of food contamination within the facility. They can also damage your equipment and compromise the infrastructure of the building. It’s so critical to stay ahead of pest control because an infestation is difficult to eliminate. Take preventative measures to avoid infestation by sealing off any cracks or openings where pests may enter the facility. Use mesh over vents in the ceilings to keep small animals, rodents and birds out.

Make sure that your cleaning and sanitizing routines are strictly followed. Remove waste from the floors promptly and make sure all waste is removed from the facility as soon as possible.

Use Proper Food Storage

If food is not stored well, it will attract pests and bacteria and other contaminants may get onto the food. Always use airtight containers to store ingredients and make sure that all food is stored at the appropriate temperature. Any raw products including meat, fish and poultry need to be stored in a cold place and away from other ingredients to prevent cross contamination.

Any products that have been completed and are awaiting transportation to stores should be stored in a separate area away from any raw ingredients.

Create a Cleaning and Sanitizing Program

Having a strict cleaning and sanitation routine that all workers adhere to is critical to food safety. Examine best practices in the industry and implement similar procedures for your food plant. MCA Group specializes in professional food plant sanitation, and our team will be happy to help you maintain a cleaning and sanitizing program you can count on to promote food safety.