Picture this: you’ve just opened the storage closet and—ugh—the cotton mops are still damp, heavy, and smell faintly like yesterday’s chili spill. Ever wondered if there’s a smarter, lighter, and, frankly, less icky way to shine your floors?

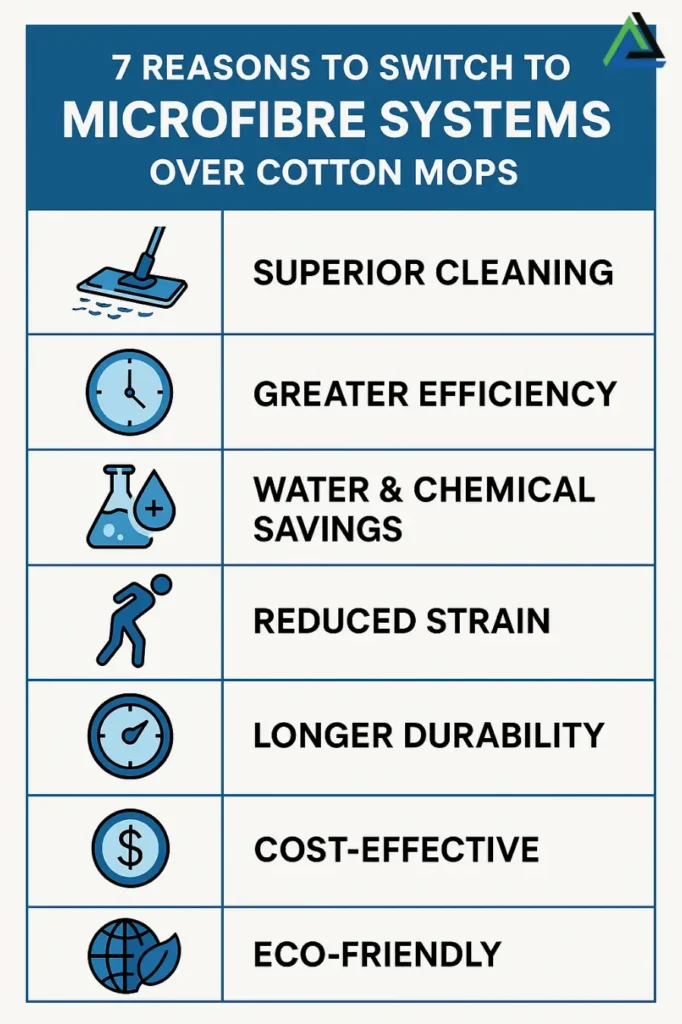

Here’s the kicker… there is, and it’s spelled microfibre. But wait… isn’t a mop just a mop? Hang tight as we unpack the benefits of microfibre systems over cotton mops—in short, why the new kid on the custodial block makes the old yarn look, um, positively prehistoric.

The Cleaning Revolution: Why Microfibre Tops Cotton

In the late 1990s, European hospitals started swapping bulky cotton loops for sleek microfibre pads. The result? Nurses reported floors that looked and felt cleaner—no lingering grit underfoot, no dull streaks. You’ll sense the difference the moment your shoe squeaks lightly across a freshly micro-fibred corridor rather than sticking to a damp cotton film.

Microfibre’s split-fiber construction creates millions of tiny hooks. Each one grabs dirt, oil, and microbes the way Velcro grabs fuzz. Cotton, by contrast, mostly pushes debris around. Rhetorical question: why spread the mess you’re trying to erase?

Split fibers also mean surface area. A single microfibre strand has 4× the cleaning contact of a cotton fiber of the same diameter. Multiply by thousands of strands packed into one pad and—voila—faster pass, better pick-up.

How Microfibre Technology Works

Fiber Diameter & Surface Area

Microfibre threads are <1 denier—thinner than a human hair. This slim size increases surface area exponentially. Each drag across tile pulls soils into microscopic nooks, locking them away until laundering. Imagine wiping a spill with sandpaper-fine threads; you’d collect way more liquid than with rope-thick yarns, right?

Capillary Action Explained

Capillarity inside the split fibers draws up to 7× their weight in fluid. Cotton absorbs, sure, but then drips. Microfibre wicks and holds, leaving floors nearly dry in one pass—no puddles, no slip warnings. Parents, caretakers, maintenance leads: feel the peace of mind when toddlers, patients, or staff stride across moments later without skids.

Speed & Efficiency on the Floor

Custodial crews at a 25,000-m² mall in Bengaluru switched to flat microfibre frames. Their nightly routine shrank from four hours to just under three—a 70 % faster turn-around in high-traffic zones. Multiply that hour saved by 365 days, and you’ve got an extra 365 crew-hours yearly.

How? Lightweight pads glide. There’s no bucket sloshing beside you; pre-soaked pads click on, clean 20 m², click off. Reach corners, kick plates, elevator tracks in one fluid motion. Your staff’s wrists will thank you.

Water & Chemical Savings

Microfibre systems rely on precise dampening—about 100 ml of solution per pad. Compare that with a traditional cotton bucket holding 10 L. Quick math: that’s up to 95 % less water per shift. Fewer chemicals follow suit, which means less environmental load and lower procurement spend.

Picture a hotel housekeeper: instead of hauling a 12-kg mop-bucket combo, she pockets eight pre-treated pads in a tote. No splashes. No chlorine fumes. Just swipe, flip, done.

Hygienic Edge: Germ Capture & Removal

Need hardcore proof? A 2018 clinical study published in the American Journal of Infection Control found microfibre removed 99 % of Clostridioides difficile spores with plain water—cotton hit only 30 % with bleach.² The split fibers physically trap microbes; hot-wash laundering flushes them away.

Rhetorical question two: wouldn’t you rather eliminate pathogens than perfume them with lemon scent?

Ergonomics & Worker Safety

Microfibre pads weigh roughly 90 g dry; wet cotton heads can exceed 700 g. That mass difference slashes push/pull force by 40 %. Less shoulder strain, fewer repetitive-stress claims. OSHA notes that every 1 kg reduction at the handle tip can cut lower-back torque by 15 %. Feel the lightness; hear less groaning at end-of-shift stretch circles.

Durability & Lifecycle Cost Analysis

Cotton frays quickly—around 30 washes before strings knot or mildew. Quality microfibre pads? Up to 500 washes. Do the math: even at 7× the upfront price, microfibre wins by a landslide before year one ends. Facilities managers love charts; here’s a quick word-picture—microfibre’s cost line slopes gently upward, cotton’s spikes like a porcupine.

Environmental Sustainability Impact

Lower water and chemical use already shrink your footprint, but there’s more. A single cotton mop demands about 5,000 L of water to grow the cotton alone. Microfibre is petroleum-based yet lasts 15–20× longer, offsetting its initial carbon cost within months. The EPA’s Safer Choice program flags microfibre as a preferred technology for green cleaning (see their guidance here). Feel the planet exhale, just a bit.

Real-World Case Studies

Hospital Wing, Chennai: After swapping cotton loops for colour-coded microfibre pads, surface ATP counts dropped 33 % in eight weeks. Healthcare-acquired infections fell from 9.1 to 6.3 per 1,000 patient-days—saving the wing ₹1.2 million on antibiotics.

Corporate HQ, Sydney: Annual floor-finish cycles fell from six to two, courtesy of reduced abrasion. Facility director Lisa Martin calls microfibre “the budget line that keeps giving.”

Choosing the Right Microfibre System

- Flat Pad Frames — best for smooth vinyl or stone.

- Pocket/Flip Pads — great for baseboards.

- Twist-Loop String — still microfibre but holds extra liquid for quarry tile kitchens.

Match pad density (g/m²) to soil load. High-traffic transit stations? Opt for ≥450 g/m²

Training Your Team for Success

- Color-Code Pads—blue for patient rooms, red for restrooms.

- Dose Right—label 500 ml squeeze bottles; 100 ml per pad.

- Swap Often—one pad per room; never re-dip a dirty pad.

A 30-minute microfibre boot camp equips staff faster than you can say “triple-loop yarn.”

Common Myths Debunked

“Microfibre scratches polished marble.” Um… no. Fibers are softer than calcium carbonate; debris causes scratches—shake pads out.

“You can’t use disinfectant.” Actually, microfibre works with quats; just avoid softeners that clog pores.

Maintenance & Laundering Best Practices

- Wash pads in <60 °C water with mild detergent.

- No bleach or fabric softener—both ruin split fibers.

- Tumble dry low or air-hang; high heat shortens life.

Follow this, and your pads will outlive three fiscal budgets.

When Cotton Might Still Win

High-heat autoclave environments above 90 °C can fuse microfibre. Also, coarse aggregate floors can snag pads—cotton loops might glide more easily here. Identify niche zones and mix systems intelligently.

Final Verdict & Next Steps

Microfibre isn’t just a modern fad—it’s a measurable leap forward in speed, hygiene, safety, and cost. Ready to upgrade? Audit your current consumables, pilot microfibre in one wing, and track the metrics we covered. You’ll never look back … except maybe to marvel at the shine.

Frequently Asked Questions

Q1. Is microfibre safe for hardwood floors?

Yes. Soft split fibers lift grit that scratches polyurethane, leaving a streak-free finish without excessive moisture.

Q2. How long do microfibre pads really last?

High-quality pads last up to 500 commercial launders—typically two-plus years in daily service.

Q3. Can I disinfect a microfibre mop head?

Absolutely. Wash at 60 °C with an alkaline detergent, or soak in quaternary ammonium per label directions.

Q4. Does microfibre release micro-plastics?

Minimal during laundering; a filter bag like Guppyfriend can capture stray fibers.

Q5. Are there color standards?

Many facilities adopt red for restrooms, blue for general areas, green for food prep, preventing cross-contamination.

Q6. What’s the upfront cost difference?

Expect to pay 5–7× more per pad, offset by at least 15× greater lifespan and chemical savings.