Warehouse & Industrial Cleaning demands more than routine janitorial work. This guide explains why porous concrete, oil leaks and constant forklift traffic create risks, then delivers a five-stage cleaning workflow that starts with dry sweeping and ends with digital inspection logs. Readers learn practical degreasing chemistry, how to banish forklift tire marks, and which scrubber-dryer size matches their square footage. KPI dashboards—gloss levels, incident rates, labor minutes—convert shine into measurable ROI.

What you’ll get from this blog

- A step-by-step playbook for Warehouse & Industrial Cleaning that any facility manager can apply today.

- Proven degreasing solutions that extend concrete-floor life and lower slip-and-fall claims.

- Equipment and chemical tips that cut labor time by 40 % without blowing the budget.

- A data-driven KPI checklist ready for your next audit.

- Why Choose MCA Group for Warehouse & Industrial Cleaning?

Why Warehouse Floors Are a Different Beast

In an office lobby you mop up coffee, clock out, and call it a day. On a warehouse floor you battle porous concrete that drinks hydraulic oil, constant forklift traffic that bakes rubber into the surface, and airborne metal dust that scratches coatings like sandpaper. That’s why Warehouse & Industrial Cleaning is its own discipline, not just “janitorial but bigger.” Ignoring those unique soil loads shortens floor life, raises warehouse safety concerns, spikes workers’-comp premiums, and stalls production when a pallet jack skids on an oily patch.

Hidden Costs of Grease & Grime

- Micro-abrasion: grit acts like sandpaper, erasing epoxy gloss and exposing raw concrete.

- Tire damage: abrasive debris devours forklift tires—often a six-figure expense.

- Regulatory risk: OSHA inspectors love to cite wet, oily aisles for slip-and-fall hazards.

A focused Warehouse & Industrial Cleaning program attacks these costs at the root instead of chasing daily spills.

The Science of Degreasing

Every successful industrial floor care routine—think concrete floor cleaning done right—rests on chemistry:

- Dwell time: give cleaners three-to-five minutes before scrubbing.

- Agitation: cylindrical brushes cut embedded rubber better than flat pads.

- Temperature: warm water accelerates reactions without harsh fumes.

Alkaline detergents crack petroleum bonds; citrus solvents lift carbon; enzyme blends digest protein soils from food or pharma lines. Choosing green cleaning chemicals whenever possible lowers VOC exposure and scores ESG points when pitching Warehouse & Industrial Cleaning to corporate leadership.

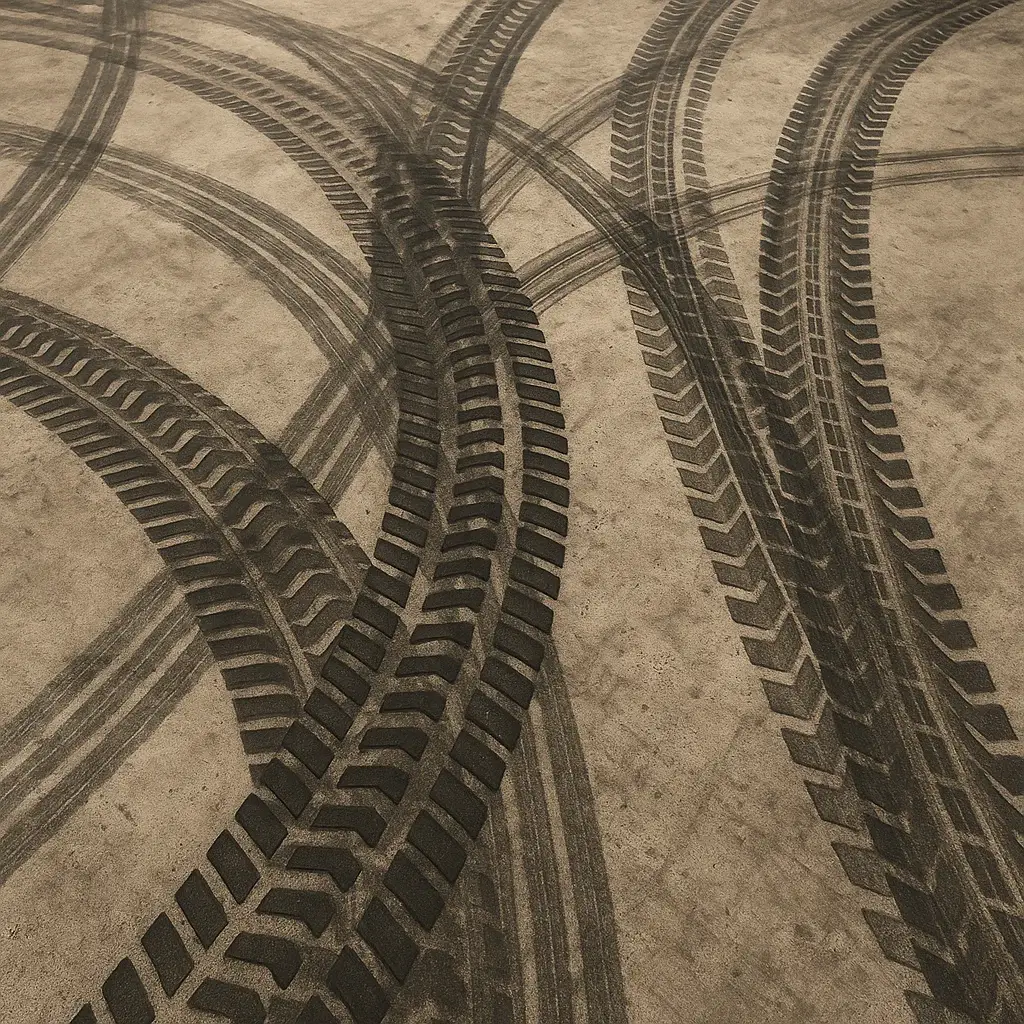

Forklift Tire Marks—Root Causes & Fast Fixes

Forklifts leave black snakes because heat softens the tire, carbon dust loosens, and pressure embeds it into micro-pores. Erase them by:

- Pre-treating with high-pH or enzymatic gel.

- Scrubbing with a ride-on scrubber-dryer fitted with medium-grit cylindrical brushes.

- Finishing with a neutralizing rinse to avoid alkaline haze.

Do it monthly; wait a quarter and marks polymerize, making removal three times harder. Regular attention keeps Warehouse & Industrial Cleaning from turning into a rescue mission.

Choosing the Right Equipment

| Facility Size (sq ft) | Best Machine | Why It Wins |

| < 20 000 | Walk-behind scrubber-dryer | Low capital cost, tight turns |

| 20 000–80 000 | Mid-size ride-on | Productivity vs. storage balance |

| > 80 000 | Large ride-on with sweeper deck | One-pass cleaning saves labor |

Cylindrical brushes trap nuts and metal shavings in the recovery tank, eliminating a separate sweep pass. Pad drivers work on sealed epoxy but struggle with forklift tire marks.

A Five-Stage Cleaning Workflow

- Dry sweep or vacuum bulky debris.

- Spot-treat oil puddles and carbon tracks with targeted degreasing solutions.

- Full-surface scrub using the machine that fits your square footage.

- Edge detail with handheld tools—grime hides where squeegees miss.

- Inspect & log results in a cloud app so supervisors see trends instantly.

Embedding this flow in your SOP makes Warehouse & Industrial Cleaning predictable and measurable, not an ad-hoc firefight.

Scheduling Without Stopping Production

- Clean in color-coded zones during shift changes.

- Sync tasks with your Warehouse Management System so crews know when aisles are free.

- Deploy IoT sensors on restroom doors and waste bins to trigger on-demand work instead of fixed rounds.

Smart timing slashes downtime yet keeps Warehouse & Industrial Cleaning front-of-mind for every safety briefing.

KPI Dashboard: Measuring What Matters

Treat cleaning like any lean process:

- Gloss meter readings before/after scrubbing.

- Incidents per 1 000 hours for slip-and-fall events.

- Labor minutes per 1 000 sq ft—a universal productivity yardstick.

- Detergent cost per cycle to spotlight savings from concentrates or green products.

Publishing these metrics shows that Warehouse & Industrial Cleaning delivers real ROI, not just cosmetic shine.

Next Steps: Turn Advice into Action

- Book a free floor audit—we’ll test gloss, porosity, and soil load in one visit.

- Pilot a ride-on scrubber for a week; measure KPIs yourself.

- Subscribe to consumables (brushes, squeegee blades) at bulk rates.

Implement just one of these offers and you’ll see why modern Warehouse & Industrial Cleaning is the fastest, safest way to protect assets, people, and profit.

By blending the right chemistry, the right machinery, and relentless KPI tracking, your facility can transform cleaning from a chore into a strategic advantage. Take the checklist above, walk your floor today, and start erasing grease, grime, and forklift tire marks for good.

Conclusion

Mastering Warehouse & Industrial Cleaning isn’t about chasing spills with a mop; it’s about running a disciplined, data-driven process that protects people, equipment, and profit. By pairing the right chemistry with purpose-built scrubber-dryers, you eliminate the root causes of grease build-up and forklift tire marks before they erode coatings and safety records. A five-stage workflow—dry sweep, spot-treat, full-surface scrub, edge detailing, and digital inspection—turns floor care into a repeatable production line rather than an ad-hoc firefight.

When you track hard metrics like gloss readings, slip incidents per 1,000 hours, and labor minutes per 1,000 sq ft, cleaning ceases to be a cost center and becomes a visible contributor to ROI.

Start small: map your zones, pilot a ride-on scrubber, and log results for two weeks. The uplift in safety, shine, and budget savings will speak louder than any marketing brochure. Invest once in systematic Warehouse & Industrial Cleaning, and your floors—and balance sheet—will keep paying dividends for years to come.

Why Choose MCA Group for Warehouse & Industrial Cleaning?

Your warehouse or plant floor isn’t the place for cut-rate cleaners; it’s a mission-critical asset that protects millions in inventory, equipment and people. Here’s why MCA Group is the partner that keeps it running safely—and profitably.

Three Decades of Proven Expertise

For 30-plus years MCA Group’s crews have tackled everything from 10,000 sq ft distribution hubs to nuclear-power facilities. That depth means faster problem-solving on your floor—and zero learning curve on ours.

Measurable Track Record

- 5,000+ businesses served

- 96.2% customer-approval rating

- 99.9% retention rate—clients stay because results stick.

Numbers like that don’t happen by accident; they’re built on standardized SOPs, supervisor signoffs and cloud-based KPI tracking you can monitor in real time.